Vacuum dryer

>Pure water machine series

>Gearbox_cleaning_machine

>Optical Ultrasonic Cleaning Machine

>Micro_ultrasonic_cleaning_machine

>Single_slot_ultrasonic_cleaning_machine

>Double_slot_ultrasonic_cleaner

>Vacuum_ultrasonic_cleaning_machine

>Manual_ultrasonic_cleaning_machine

>Automotive_ultrasonic_cleaning_machine

>Through_spray_ultrasonic_cleaning_machine

>Semi_automatic_ultrasonic_cleaning_machine

>High_pressure_spray_rotary_ultrasonic_cleaner

>Three_slot_ultrasonic_cleaning_machine_series

>Automatic_suspension_chain_ultrasonic_cleaning_equipment

>Crystal crystal. Piezoelectric crystal ultrasonic cleaning machine series

>New technology release

>Frequently Asked Questions

>cleaning_video

>

189-2649-3933

address:E building,Hongyuan Area,HuaChang Rd.Dalan Street,Bao’an Area,Shenzhen

tel:+86-755-28035588

+86 18926493933

tax:+86-755-28035088

email:sz008@vip.163.com

Technical Analysis of VGT-1309FS Ultrasonic Cleaner

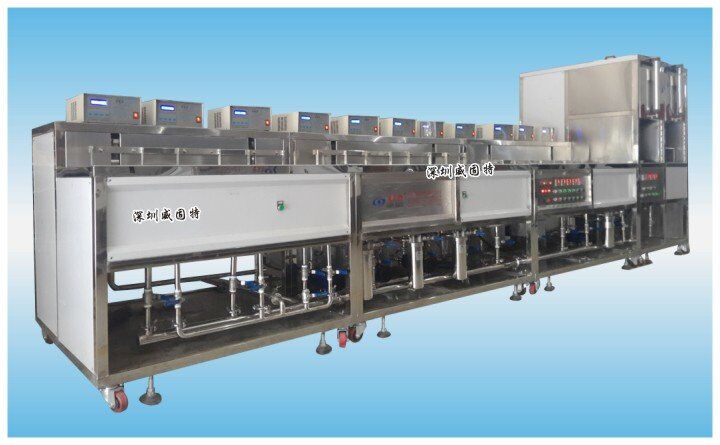

In high-end laser processing and optical systems, the cleanliness of protective lenses directly determines the working efficiency and lifespan of the equipment. In response to this precise demand, the VGT-1309FS ultrasonic cleaning machine from Vigut, through a 13-tank modular design and centrifugal spin-drying technology, provides an industrial cleaning solution for laser protection lenses and has become a key device for pre-treatment of optical coating.

I. Core Technology: Engineering Implementation of Precision Cleaning

Multi-tank collaborative cleaning system

The equipment adopts a 13-station tank layout, covering the entire process including cleaning, rinsing, slow pulling dehydration and centrifugal spin-drying. The modular structure supports free disassembly and combination according to process requirements. For example, for the pre-coating cleaning of laser lenses, water-based cleaning agent tanks and high-purity water rinsing tanks can be configured to effectively remove dust, polishing powder and organic residues. The rinsing tank is equipped with an ultrasonic cavitation and temperature control system, combined with a multi-layer filtration device, to ensure no residue of cleaning agents and meet the optical-grade cleaning standards.

2. Dynamic cleaning and strengthening technology

Sweep frequency ultrasonic: It adopts IGBT control technology to achieve sweep frequency output, with power continuously adjustable from 40% to 99%, avoiding cleaning blind spots caused by fixed frequencies and protecting the coating layer of the lenses at the same time.

Mechanical tossing: Driven by a lead screw transmission mechanism, the cleaning basket moves up and down at high frequency (the tossing amplitude is adjustable), increasing the shearing force between the lens surface and the liquid, and accelerating the shedding of dirt from deep holes and edges.

3. Intelligent Control and Drying Innovation

The touch screen human-machine interface supports presetting and storing multiple sets of cleaning process parameters (such as adjustable time from 2 to 20 minutes). After the cleaning is completed, the mechanical hand automatically grabs the material basket and enters the centrifugal spin-drying station. A clean hot air buffer station can be optionally equipped to achieve "zero-contact" drying and prevent secondary pollution.

Ii. Key Points for Safe Operation and Precise Control:

1. Standardized start-stop process:

Before starting up, it is necessary to ensure that the liquid level in the tank reaches 1/2 to 3/4 of the tank depth. It is strictly prohibited to start the machine without load. The recommended cleaning solution is a neutral water-based solvent, and the temperature should be ≤80℃. The continuous operation should not exceed 4 hours. Before shutting down, reset the power knob to zero, delay for 3 to 6 minutes to dissipate heat, and then turn off the power.

2. Parameter adaptability adjustment

Regarding the characteristics of laser lenses:

Time: Set according to the degree of pollution (usually 3 to 10 minutes). An excessively long time may damage the microstructure.

Power: Initially set to medium (approximately 60%), gradually increasing for stubborn pollutants;

Temperature: 40℃-60℃ can enhance the activity of the cleaning agent, but it needs to be matched with the heat resistance of the lens substrate.

3. Safety Protection design

The equipment is equipped with dual photoelectric protection switches and emergency stop buttons. The handling mechanism adopts shock-absorbing design (lateral moving speed ≤120mm/s) to prevent lens collision. The electrical control system complies with the IP54 protection grade, and the grounding terminal is forcibly connected to prevent induced electric damage to the workpiece.

Iii. Maintenance Strategy: Ensure long-term Stable operation

Daily maintenance: After work is completed, drain the contaminated cleaning solution, rinse the filter screen and nozzles to prevent the accumulation of particles.

Monthly maintenance: Check the condition of the bearing grease, add calcium-based grease to the transmission lead screw, and test the output stability of the ultrasonic generator.

Water quality monitoring: The built-in resistivity meter is used to monitor the resistivity of pure water in real time to be greater than 15MΩ·cm, ensuring no ion residue during the rinsing stage.

Fault prevention tip: If the ultrasonic intensity weakens or abnormal noise occurs, it may be due to fouling of the transducer or generator failure. The machine should be stopped immediately and the surface of the transducer cleaned.

The VGT-1309FS from Vigut has solved the problem of micro-residue in laser-protected lenses through an engineering-grade cleaning architecture and optical process compatibility. Its value is not only reflected in the cleaning efficiency (with a minimum cycle time of 2 minutes), but also in ensuring the coating yield with monitorable process consistency. For high-precision fields such as 10,000-watt laser equipment, such devices have become the core prerequisite for avoiding the thermal lens effect of lenses and improving beam quality.

China

China English

English